Protect Your Steel From Costly Corrosion With Hot Dip Galvanizing Services

Extend the life of your steel using our hot dip galvanizing process. Reach out to the Beyond Steel team to learn more about our metal fabrication specialities and get your free quote.

How the Hot Dip Galvanizing Process Works

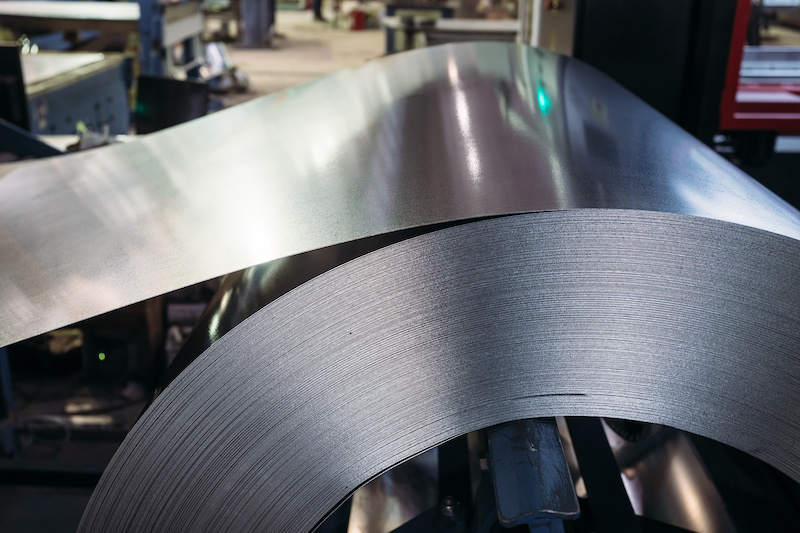

Hot dip galvanizing refers to the process of immersing steel into a kettle of molten zinc. The zinc forms a tightly bonded alloy coating when the iron in the steel metallurgically reacts. After the process is completed, the steel is left with a protective coating that prevents corrosion.

Here is the process we follow:

The Benefits of Hot Dip Galvanizing Steel

There are several advantages to using hot dip galvanizing as a corrosion prevention system.

- Save big by using this lower cost corrosion protection method.

- Get your steel material protected fast using this quick process.

- Simplify the steel coating inspection process — galvanized coatings are easy to visually inspect.

- Ensure tough resistance thanks to the metallurgical bond with the steel.

- Reduce maintenance costs over time, as hot dip galvanized steel is self-maintaining.

- Extend the life of your steel materials to 50+ years.

- Reduce environmental impact by eliminating maintenance that requires lots of energy.

What to Look for in Hot Dip Galvanizing Companies

When you’re looking to protect your steel materials, you need to work with galvanizing companies and suppliers.

There are several aspects to consider when you’re looking for the right fit, including the following:

- The size of their operations (e.g., galvanizing tools, dipping tank size)

- Their process for galvanizing steel

- The cost of their hot dip galvanizing services

- The grade of zinc they use for their hot dip galvanizing process

- The certifications they hold in your state

- The location of their facilities

- Their reputation with their customers

- The history of the organization and their level of experience

Start With the Best Metal Drilling Company in California

As a veteran owned metal steel distributor, Beyond Steel has been proudly serving California for 10+ years. Our team is focused on more than just selling products and services. We are focused on building relationships.

Learn more about how our metal and steel drilling services can set you up for success with your ambitious metal fabrication process.